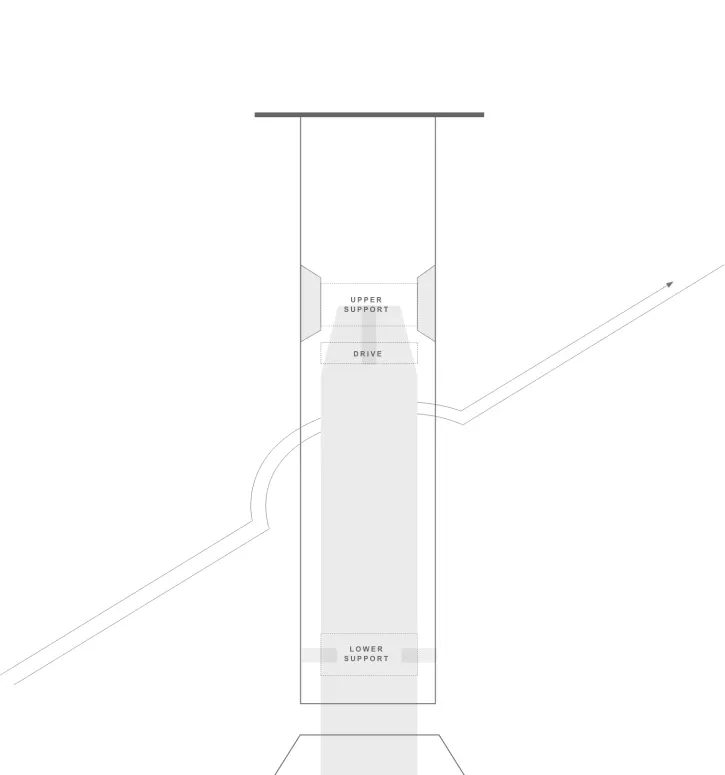

Foundations are used to mount Norsepower Rotor Sails™ to the ship's deck. The foundation transfers the load to the ship's hull, making it robust and stable. Manufacturing the foundation and the actual installation onboard is done by the shipowner and/or shipyard. Technical specifications for the typical foundation are provided by Norsepower. Installation of the foundation is most conveniently done during a regular maintenance docking.

Steel structure modifications and installation can typically be done in 7–14 days. If necessary, part of the work can be done during sailing. Automation system components (incl. sensors, Norsepower Control™ panel, optional monitoring panels) as well as the power and automation system cabling, are best installed while the ship is at a maintenance dock. If the maintenance docking period is short, part of this work can also be done while the ship is in operation.

Typical installation time, including completing of mechanical and electrical connections, is 6–12 hours per rotor sail when all other preparations are ready. In the installation phase, the product is lifted to the foundation by crane.